Overview of the injection molding industry

What is the injection molding process?

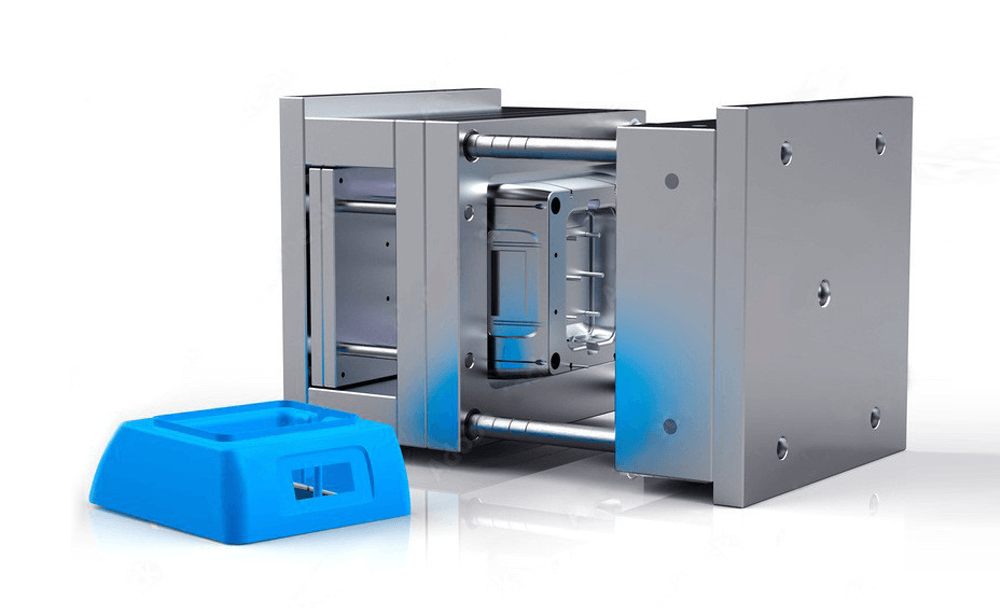

The injection molding process injects molten plastic or rubber material into a mold, which is cooled and hardened to form the desired part or product. This manufacturing method has the characteristics of high production efficiency, high precision, and good repeatability.

Development prospect of injection molding:

The industry’s future is very promising. Here are some key factors:

Growing Demand for plastic products:

Injection molding is the most common way to make plastic parts, and there is growing Demand for plastic products in various industries, including automotive, packaging, medical, and consumer products.

Technological advances:

Innovations in materials and techniques have expanded the capabilities of injection molding, including the ability to create more complex geometric shapes, shorten production cycles and improve quality control.

Sustainability:

The injection molding industry reduces waste, improves sustainability using recycled materials, and implements more efficient production processes.

Increasing automation:

Automation is increasing efficiency and reducing labor costs in the injection molding industry. Advances in robotics, machine learning, and artificial intelligence have also made production more precise and consistent.

Globalization:

The injection molding industry is global, and as globalization advances, the industry’s prospects will continue to expand.

Injection molding applications

Injection molding is widely used in a variety of industries. The following are some of the main application areas:

Automotive industry:

The automotive industry is one of the main application fields of injection molding, including body, interior, electrical appliances, lamps, tires, etc.

Electronic industry:

Injection molding is also widely used in the electronic industry, such as mobile phone shells, TV shells, computer shells, keyboards, etc.

Medical industry:

Injection molding is also widely used in manufacturing medical instruments and equipment, such as syringes, catheters, artificial heart valves, surgical instruments, etc.

Packaging industry:

Injection molding in the packaging industry is also more and more applications, such as plastic bottles, boxes, barrels, crispers, lunch boxes, etc.

Consumer goods industry:

Injection molding is also widely used in the consumer goods industry, such as home appliances, toys, office supplies, kitchen utensils, bathroom supplies, etc.

Conclusion

With the increasing requirements for injection molding technology in various industries, the industry is also developing and innovating. There are some advanced technologies and materials in the industry, such as high-speed injection molding, double injection molding, multi-color injection molding, polymer materials, etc. The emergence of these technologies and materials has expanded the application range and ability of injection molding.

In addition, the injection molding industry is constantly evolving and changing with the advance of globalization and automation. The advent of automated production lines has increased production efficiency and quality. Companies in the industry are also trying to improve the sustainability of production processes, such as using recycled materials and energy-efficient and environmentally friendly production processes.